The Science/ Engineering of snowboarding.

Ok so quick introduction, I am a first year engineering student and I’ve been on the Forums for a few months now. I’ve been thinking it would be cool to explain how and why some aspects of snowboarding are the way they are, sort of how Destin from smarter everyday explains things about many many topics.

So basically I’m starting this thread as a place to explain mostly the physics aspects of snowboarding as best as I can, feel free to ask your own questions along the way.

I am most likely going to start on why wax is important, and then lead on to related things such as: how the snow conditions actually affect the speed of the board, also explaining some of the technologies involved in snowboards like carbon reinforcements in the core etc…

Feel free to add anything if I miss things, post video’s that you find and whatever else, let’s see where this takes us, I’m just going to post things as they come, and will visit the forums at least on a daily basis so there will (hopefully) often be updates to the thread.

Why is wax important?

We all know it makes you ride faster, but how does it manage this feat?

Ok, picture this, you are cruising along with some mates when “Jono” decides to start an impromptu race down to the bottom, last one down has to buy the first round of drinks at the bar that night. obviously this situation may or may not be a likely one for many of you, you may not even have a friend called Jono. But the key point is while it is too late at that point to prepare your board for the race, I bet you are wishing you had. We all know that a well waxed board is going to be faster than a board with worn/no wax (assuming they both have the same kind of base, I will probably get into this later).

firstly I am going to discuss the basic all temp wax, this is generally what most people will be using and is a solid start to getting that little bit more speed down the hill.

All temp wax speed you up by slowing you down… no that isn’t a typo, wax in general fills in the pores in your sintered base, and then acts as a source of friction between the snow and your board. usually friction slows objects down, but due to some of the properties of the wax specifically and of snow/ice, this friction can actually melt an extremely small amount of snow under your feet. the water then acts as a lubricant, and it flows from tip to tail along tiny channels in the board, (this is why scraping wax/brushing should only ever be done in line with the board) imagine if you will that the snowboard slides along in the same way as many ice skates side by side, only the snow is melting mostly from friction instead of pressure (ice skate have 2 “blades that make an “n” shape, the water flows though the channel, much in the same way that a snowboard has many many channels.

different waxes get more complicated, they are all generally the same and work on the same principles, but they have slight changes to their composition. a cold temp wax needs to provide a little bit more friction on the snow to melt it properly, so it has additives that give it that little extra grip.

on the contrary, hot temp/ spring waxes are made for areas where the snow is already on the verge of melting and do not need to provide much friction at all, they need to repel water because there can be too much of a good thing, this leads into race waxes like fluro

for the best glide there is Fluro wax, this is wax where the hydrocarbon’s i.e Carbon and Hydrogen chains are replaced by Fluro carbons, Carbon and Fluorine, these are faster because they keep the amount of water close to the perfect amount, and they provide very little friction once the snow is melted allowing extra glide over the water.

so remember before you next head out, wax that board, it might save you a few dollars in the bar.

(sorry if this was too technical, I was trying to simplify things as much as I could, if you want to read up more, there is plenty of resources around, Wikipedia actually has a lot of good info…

The next post will likely be how to make snow in your backyard/ how snow making works in resorts.

This was a really interesting read. I always knew about the layer of water but I never thought of the wax actually creating grip/friction to create this effect.

In regards to cold and warm temp waxes, you say cold temp waxes need to create more grip, which makes perfect sense. Is it also true that cold temp waxes needed to be “harder” to resist the abrasion of the cold snow? I was always taught that this was the case.

If so, is the hardness of the wax and friction created directly related?

It would be great if you could expand on this. I am certainly interested.

This was a really interesting read. I always knew about the layer of water but I never thought of the wax actually creating grip/friction to create this effect.

In regards to cold and warm temp waxes, you say cold temp waxes need to create more grip, which makes perfect sense. Is it also true that cold temp waxes needed to be “harder” to resist the abrasion of the cold snow? I was always taught that this was the case.

If so, is the hardness of the wax and friction created directly related?

It would be great if you could expand on this. I am certainly interested.

glad you’re interested. It seems that cold waxes would indeed need to be harder, to resist abrasion, small ice crystals can more easily form in colder conditions and they can make micro scratches which will affect performance, if the wax isn’t hard enough to resist.

I don’t think that the hardness of wax and friction are directly related, I’m not 100% sure on the compounds they add, but it could easily be the case that there is a compound they add to cold wax which increases friction and hardness, it could just as easily be that they have certain additives for hardness and others for friction, I couldn’t really tell without contacting some companies and asking for super secret info :( but it seems like a reasonable assumption.

Anyway So Today I am going to quickly go over the art of making artificial snow, I’ve wanted to try this at home for a while but the equipment needed is too expensive to justify buying just for making snow, and the water bill would go though the roof…

In resorts you will have probably noticed there are two kinds of snow guns, the “cannons” which are short fat and stubby looking things which have large fans.  (image courtesy of wikipedia)

(image courtesy of wikipedia)

and the thin pipes sticking around everywhere, snow “lances”.  (also from wikipedia)

(also from wikipedia)

there are also internal and external mix snow making techniques, which are generally what you hear when people talk about making snow at home.

but all of the above revolve around the same concepts. cold water+cold air=ice

I will start with standard internal and external mix guns.

these are mad up of a high pressure water source, a high pressure air source, tubes, and high precision nozzles.

these kind of snow guns are generally low to the ground and require very high pressure air to make sure the crystals freeze.

the compressed air both pushes the water higher into the air giving it more time to freeze before it hits the ground, but more essentially as any gas expands it cools, meaning that the temperatures of your snow can be much lower than the air around. (there are many variables, affected by humidity, wind etc… but it is actually possible to make snow using this method in temperatures up to about 2 degrees celcius if conditions are right)

here is an image of an internal mix snow gun  (courtesy of Destin from smarter every day, http://smartereveryday.tumblr.com/ and https://www.youtube.com/user/destinws2/)

(courtesy of Destin from smarter every day, http://smartereveryday.tumblr.com/ and https://www.youtube.com/user/destinws2/)

you can see that the air and the water are combined inside a chamber. external mix the air simply runs along side the water atomisation nozzle (which mists the water finely allowing git to freeze more easily) and the air cools it and blows it, after going though it’s own nozzles. external mix is less efficient in general but there is less risk of back pressure/ freezing in the pipes so it’s easier to implement.

the 2 resort kinds “cannon” and “lance” are variations of these 2 designs. the “Cannon” is similar to an external mix gun in some ways, as it has fine misting nozzles, and a large fan which can generate some pressure and cooling. the main difference is that because these are made for ski resorts they can rely on the air temps being very low, so the fan actually pushes the misted water 10’s of meters into the air giving it a lot of airtime to cool.

the lance is (usually) also external mixing and is set atop a pole to give it its airtime, this gives it an inherent saving in energy, as you don’t need to turn a huge fan. but generally the snow quality made is worse. and are also more sensitive to the wind blowing snow off course etc…

this is why most resorts have some sort of combination of snow guns, (even if along certain runs you only see one kind)

ahhh i like science!!

The whole wax thing sort of answered a question ive been wondering for a while as to why board bases arent dimpled like a golf ball to minimize friction. Years ago there was a body board made by morey called the 8tx. It had a dimpled base

It was meant to reduce friction with the water by trapping air bubbles and making a sort of riding on air type of arrangement. I wondered why this hadnt been applied to snowboard bases as i assumed that like with anything the less friction the faster you would go, but now i see why this might not be the case.

BUT to throw that idea on its head, is there a reason why you couldnt fill these dimples (obviously make them smaller than the bodyboard) and that way you’d have a ‘reserve’ of wax that would wear down over time but negate the need for constant regular board waxing, it would only be a small surface of wax creating the friction as apposed to a whole boards base???

Sapient Snowboards used the dimple technology on some of their board bases (when they were still in business).

ahh i didnt think i would have been the first to think of it, too simple of an idea for the ideas boffins at snowboard makers to not think of and pass on to us as the next big thing.

Ok then, what about a convexed base, sort of like a catamaran based snowboard. Again less surface area and less friction, or maybe those dudes that came up with the snowboard brake can team up with ben lexen and help design a winged keel for a snowboard!! ![]()

Yeah my original DC board had a “Structurn” base which was based on that idea

http://www.snowdb.com/technologies/dc/2011/structurn-base-finish

It was the slowest board I’ve ridden in spring conditions and a pain to wax!

Stepchild used to do a dimpled base on their high end boards!!!!!

Not sure if they still do?????

My Structurn Base is plenty fast, Dave!!!!! What sort of wax did ya use?????

technically almost every board out there today is “dimpled” to some degree, there are 2 kinds of friction “Dry” which is what melts the snow into a water layer, and “wet” which is what gives you a better glide on the layer of water, the trick is to optimise the 2 types so that the board goes fast, if the ratio’s aren’t right you will either not make enough water to slide on, or you will make enough water but not be able to slide on it properly.

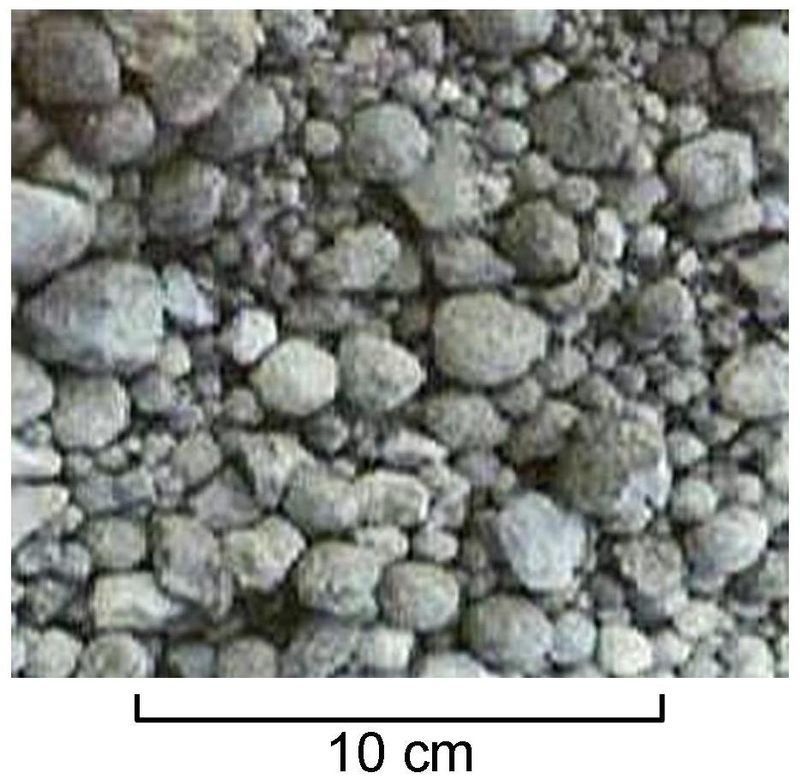

as per dimples go, the majority of boards use sintered bases. these are made from a powder which is “sintered” which is esetially heating and compacting it, so that you form a solid from a powder without needing to melt it. depending on how you control the process there will be bigger or smaller gaps between the “grains” of material. kinda like this  (from wikipedia)

(from wikipedia)

these dimples are very small, but they are still there and they do have a major effect on how much wet friction there is. that said I’m not sure why they can’t make the dimples larger around the center of the base, because the melting mostly happens at the first contact point, i.e nose of the board, or tail if you are riding switch.

Yeah, and that’s where the wax is actually absorbed into!!!!! the “Gaps”!!!!!

But there are bases that have pronounced dimples and/or “structure” formed into the material!!!!!

pretty sure that shouldn’t read 10cm!

pretty sure that shouldn’t read 10cm!

It’s a picture of the fish pond gravel!!!!!

no idea what the pic is of, but it’s from the wikipedia page on sintering, it’d be more like 1mm or so on a board.

but yea waxed is absorbed into the gaps, once you scrape it and brush it, some of the gaps will be only party filled so there will be an uneven surface.

didn’t know that there would be dimpled boards with the surface visible to the eye, maybe it was too expensive for the performance gains, or something like that.

I know they are looking into making car bodies that become dimpled over a certain speed (where the reduction in drag though turbulence is possible) so maybe similar technologies can make it into snowboarding eventually, but I’d say it’d be a price/ ease of manufacture problem for now, as to why they aren’t obviously dimpled.

ahhh i like science!!

The whole wax thing sort of answered a question ive been wondering for a while as to why board bases arent dimpled like a golf ball to minimize friction. Years ago there was a body board made by morey called the 8tx. It had a dimpled base

I remember when these came out. I had a picture of one on my year 10 school diary cos I wanted one so bad. hahaha